Sieves are a beautiful invention, as I’ve said before. At 10-20% w/v, 3A molecular sieves will dry every common solvent except acetone as well or significantly better than a solvent still [1, 2]. A bottle of sieves/solvent is also far less likely to catch on fire and is far cheaper to maintain (no argon or water lines).

Sieves are a beautiful invention, as I’ve said before. At 10-20% w/v, 3A molecular sieves will dry every common solvent except acetone as well or significantly better than a solvent still [1, 2]. A bottle of sieves/solvent is also far less likely to catch on fire and is far cheaper to maintain (no argon or water lines).

Unfortunately, sieves are shipped saturated with water and must be dried before use. Sieves actually absorb water at 120 degC, so a conventional drying oven is not up to the task.

Conventional wisdom is that heating to 300 degC or greater at atmospheric pressure will dry sieves, and this temperature can be reduced somewhat under vacuum [3]. Experimentally I had some success heating to ~200 degC overnight in a vacuum oven, but was never quite sure that the sieves were fully active [4].

Holding the sieves at 350 degC for 3.5 hours is the right amount of overkill. While this is a temperature out of reach of most drying ovens, it barely hits “medium” on the temperature setting of a glassblower’s annealing oven.

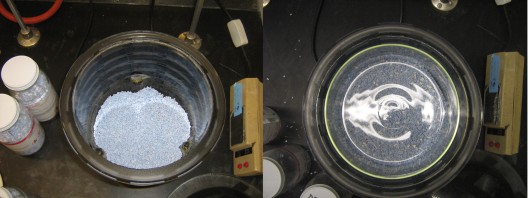

When drying sieves go for economy of scale. Large recrystallization dishes will hold up to about 4 kg at a time (190×100 mm), and have the advantage of being ~1.5 cm smaller in diametre than an average size glass desiccator. Once they’ve been activated let the sieves cool to ~150 degC in the annealing oven, then transfer them over. Take care to fill the desiccator with drying agent to at least the height of the inner glass studs, as contact between the hot recrystallizing dish and cold ceramic/glass will almost certainly shatter one or both.

Take care to cover the glass baffles (left) with drierite. The recrystallization dish should fit within the dessicator without touching the sides (right).

Active sieves can be stored in any convenient glass container, provided the lid is well sealed. Double wrapped parafilm works well, sufficient to keep the sieves active for at least six months.

[1] Sieves are mildly basic, which triggers aldol reactions in acetone and can decompose some compounds. For example, after prolonged storage (8-10 months) of triethylamine over 3A sieves I’ve noticed a yellow discolouration in the solvent, likely due to formation of diethylamine.

[2] Larger sieves are recommended for the drying of some solvents (ie. 5A for pyridine). The difference in final water concentration is pretty negligible though, and the larger sieves can trap solvents like methanol, reducing their utility.

[3] Flame drying in a roundbottom flask under vacuum was standard approach when I arrived in Alberta, but was good for only small quantities.

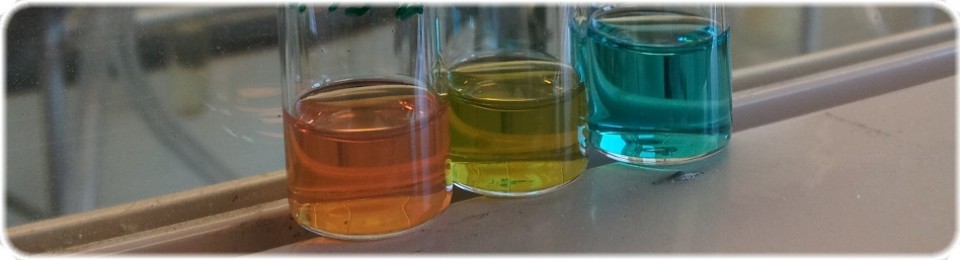

[4] How to determine if molecular sieves are active: Place a small quantity on a gloved hand, and add roughly two volume equivalents of water. If the sieves are fully active they will become too hot to hold, even through the glove.

What about microwave activation (obviously suitable for smaller scale)?

See, for example:

– doi: 10.1071/CH08450 (none other than KAPPE!)

– there is also this thesis from UAT, “Microwave enhanced regeneration of absorbents” (1993) by A.P. Weissenberger, though it seems to be one of a series concerning rather the recovery of adsorbed organic volatile

– a series of recent articles by Sarbu and Calinescu (Google Scholar) and references therein

– Singh – Microwave Regeneration of Molecular Sieves 1984 (available online)

– etc.

Do you know anything about their absorption speed? I mean, can it be that you dry them at 350 deg, then cool down, go to find a bottle, and when you’re back, the sieves are already inactive?

In solvent the sieves work over ~48 hours, so I don’t expect them to inactivate too quickly in air. You certainly don’t want to leave them on the bench for days on end, but an hour or so should be OK.

Good point on the microwave mamid. From what I’ve heard that works well, provided you stop heating before the sieves start to glow.

Do you have any suggestions for transferring the sieves from the glassblowers furnace down the hall to our lab safely?

Let them cool for ~1hr in the oven, then transfer the recrystallization dish to a desiccator (see pic above). The desiccator can be sealed and carried around easily.

For activation of 3A/4A MS with a domestic microwave oven (50W), I’ve had great success with the following protocol. This method affords super-activated sieves that are significantly drier than those prepared in a vacuum oven or arrive pre-activated by the manufacturer:

Pour the sieves into several 15 cm pyrex petri dishes (or similar low-sided dish) in a ~5 mm thick layer, and nuke them for 3 x 5 min at full power. Between each 5 min nuking step, open the microwave door and cool sieves for 3-5 min with the aid of a small electric fan. This also serves to vent the pocket of humid air that accumulates in the microwave.

After MW activation, transfer sieves to a crystallization dish & cool in a vacuum desiccator for ~2-4 hrs a la Brandon’s method. Transfer them to an airtight glass bottle, purge with dry argon or N2, and store in decent desiccator. They can be stored in this manner for at least several months with little loss of activity.

The only potential drawback is that if the sieves are overheated by extended microwaving, they can become fragile and prone to cracking.

-Ian

Hi,

I need to generate some very clean methanol to fix cells and would like to use 3A molecular sieves for this. We have some in the lab, but they are most likely inactive, no one really knows. So, I want to re-activate them, but have never done this before. I really like the microwave protocol Ian described, but we don’t have crystallization dishes, can I use a glass beaker instead? How will I know when they are done if I’m using a different power microwave? I’d like to avoid cracking them, but don’t want to heat them for too short a time, obviously.

I intend to activate small amounts and immediately use them to dry our methanol (10-20% w/v as described in the article). What is the best way to combine the sieves with methanol? Do I add the sieves to methanol, or is better to put the sieves in a glass bottle first and then add methanol?

Thanks!

A beaker would be fine. The process itself is rather qualitative, so I would start with a brief microwave pulse and build up from there. To verify that the sieves are active add water to a small sample. If they get very hot, you’re good!

How you mix the sieves and methanol doesn’t matter.

Thanks for the answer Brandon. I’ve activated my sieves and added methanol to it. Now, the solution has become a little murky. Initially I could see many small bubbles coming up from the sieves, but the cloudiness has not really gone away. Is this normal, will it go away over time (it’s been about 30min), or should I do something to make the solution clear again before using it?

Sounds like dusty sieves. If things don’t settle after 16hr I would be concerned, but otherwise that’s perfectly normal.

Having a discussion with our post doc about trying these and we have a few issues:

1) Is there a good way to test these, other then hauling the solvent into the box and testing with benzophenone? We are doing some very, very sensitive chemistry (i.e. conditions that are fine for n-BuLi are too wet for this)

2) Have any studies been done of them vs benzophenone purple? The cities paper only dried to blue, which isn’t nearly enough; All those comments about ‘drier then your sodium’ are wrong; The citied paper only refluxed to blue, which isn’t very dry. You need to reflux for another 3-7 days after that to reach purple, which is when your THF is properly dried. However, I can’t find any mention of what ppm level this is.

3) We have an SPS that doesn’t dry THF nearly well enough; we actually use it as a predry for the sodium still. If it is full of molecular sieves then that doesn’t say good things about how dry they actually get things…https://chemtips.wordpress.com/2014/12/01/how-to-activate-molecular-sieves/#comment-form-load-service:Twitter

Unfortunately I’ve never needed conditions as dry as the ones you’re describing. Repeated passage over sieves (ie. from one bottle to another) might get you to the level you need, but you’re going to have to do a Karl-Fischer or similar to get an accurate view of water concentrations.

A quick search turns up this JOVE article, which states purple benzophenone = <10 ppm water. I'm not 100% convinced, but it's a start.

I recomend this paper: J. Org. Chem. Vol 75, N 24, 2010, p8531. They state that THF after drying with molecular sieves (20% m/v) for 72 h has a residual water content of 4 ppm.

Anneke,

If you’re worried about the “dust” from fresh sieves contaminating your MeOH (or other solvents), its best to first rinse the dried/activated sieves 2-3 times with MeOH or the solvent you’ll be drying before adding them to the bottle of MeOH/solvent that you want to dry. I find that a fine wire mesh basket comes in handy for collecting the washed sieves.

Also, to effectively dry MeOH and other lower alcohols (EtOH, iPrOH etc), you must use at least 20% w/v sieves.

See this paper for reference:

http://pubs.acs.org/doi/abs/10.1021/jo101589h

Is there a time limit for storage of the solvent with the molecular sieves? (Necessary to keep the water content of 3-4 ppm)

There’s a minimum time required for the sieves to work, but there doesn’t seem to be a maximum. I’ve kept bottles filled with sieves for months on end without issue.

Just make sure you parafilm the caps to ensure a tight seal.

Hi Brandon…are you still in Alberta ? I am there as well and wouldn’t mind contacting you via email and then maybe by phone. I have some questions and prefer to actually talk rather than texting.

Ian better check his microwave wattage again. My crappy little domestic is 450 watts and it’s pretty crappy. I put some sieves in a small pyrex dish for 5 mins and I could still touch them without burning my fingers. His has to be at least 1000 watts.

Hmmm … my microwave oven gets a small amount of sieves in a pyrex bowl pretty hot but no wheres near 350C. Why can’t a guy say use a toaster oven at 450F for a much longer time rather- than use 350C for a shorter time ? But how can a microwave do it at much lower temps ?

Another question … why and/or how do the sieves heat up when absorbing water ? That almost seems like an over unity reaction.

Alright, there’s a bit to unpack here.

1) I’m no longer at Alberta. As of August 2015 I’m an assistant professor at Concordia University, in Montreal.

2) Sieves form a very strong bond to water, which is why they need to be heated to 350 degC for a pretty long period of time to fully activate them. Trying to replicate the process at 450 F (232 degC) would be about as effective as trying to hammer a jello nail through a brick wall.

3) Microwaves aren’t heating to just 350 C. When properly done the sieves are going to be much hotter, which allows us to shorten the drying time from hours to minutes.

4) Sieves heat when water is added because we’re forming a large number of strong water/sieve interactions. This is very enthalpically favourable,and the energy produced is largely dissipated as heat.

hello i have gas dryer are in regeneration for 5 days due to stop the production , is this can has negative impact on life of molecular sieves

what we do in our lab is

1. we wash sieves first with acetone

2. then dry them normally in oven at 100 C

3. take them in a RB/conical under nitrogen apply vacuum

4. then using burner under vacuum we keep it for a minimum of 20 mins with purging nitrogen in between

i think this is enough to activate sieves in a simple and quick process

The statement that sieves actually adsorb water at 125C is important. Can you please explain where in the paper you cite you draw that inference from?

Sorry – I just read the article more fully and the inference drawn is incorrect, even nonsensical. The absorbance of water by sieves will happen at any temperature. There is nothing in the article to indicate it peaks at 120C. However, even if it did that only renders heating to 120C insufficient if the heating is done in the presence of water. Since water boils at 100C and can presumably leave the heating area – the oven – there would generally be little to no water vapor present to be absorbed into the sieves. Your article, while helpful in many ways, provides no clear indication that heating to 350C is necessary or even more efficient than a much lower temperature (a temperature used in our lab all the time). I would suspect that heating to 350C might even significantly reduce the ‘lifetime’ of the sieves through thermal degradation – mainly fracturing into smaller and smaller bits. Seeking feedback

I’m simply stating that heating to 120 degC will not desorp water from the sieves. Water’s boiling point in solution is immaterial, since the sieves are already wet and the water/sieve interactions are incredibly strong. I’m not certain what temperature is required to break these interactions, but I do know that 350 degC is more than sufficient (hence “overkill”).

I can’t comment on the lifetime of the sieves.

I am a huge fan of sieves – professors in my orbit are considering mothballing stills, largely based on Williams & Lawton (JOC, 2010, 75, 8351-8354), however, your well meaning posts are not helpful to that end. Ovens capable of reaching 350C are not common in laboratories (or they are chuck full of other heating projects that don’t require 350C) so your suggestion that such an oven is required makes the transition from stills to sieves more burdensome. “More than sufficient” is not just better sufficiency; wasteful comes to mind. As I have been discussing the matter with colleagues, the suggestion that 350C is necessary has been largely dismissed by those workers/professors who have been regularly using sieves for years. The workers in the paper you cite I think were trying to reach ultimate dryness as they had complex physical assays they were trying to perform to better understand the nature of the zeolite matrix.

How to regenerate x5 zeolite molecular Sieves? We recharge the sieve of Zeolite, and we have the Zeolite Used and we wanted to develop a machine for your regeneration

https://www.sigmaaldrich.com/chemistry/chemical-synthesis/learning-center/technical-bulletins/al-1430/molecular-sieves.html

I believe the yellowing of triethylamine is due to N-oxide formation.

I have had problems heating them over 200 degrees under a vacuum I bounced them and they were getting a gray burn-like color. Do you know why this is and how to prevent it?

I use the microwave now way much faster and easily 🙂 the only inconvenience is that you can not do a lot at once.

How hot do regular mol sieves get when absorbing water? I’m concerned about flash points of benzaldehyde (around 63 C) being hit, is that a relevant concern… will be drying benzaldehyde/MA as it forms a Schiff base.

It’s only really a concern when you’re putting water directly on them. Provided you’re drying more than a millilitre or two of benzaldehyde you should be fine.

If you’re trying to dry 4+ litres of benzaldehyde I’d start worrying about potential runaway reactions again, but it really shouldn’t be a problem at research lab scales.

Thanks Brandon… just drying maybe 30 g Benzaldehyde / 30 g Methyl Anthranilate… so it sounds safe … I’ll clean these with perfumers alc. dry with a towel … heat 3-4X 4 min in the microwave – then drop a layer of the sieves into an Erlenmeyer and let it do its thing for 24-48 hours?