Tags

academic job search, assistant professor, biochemistry, biology, career, chalk talk, chemical biology, chemistry, dream job, interview advice, job advice, luck, mentors, public lecture, research, research plan, signature research idea, teaching objectives, teaching statement, tenure track

Big news!

I will be joining the faculty of Concordia University as an assistant professor in Biochemistry on August 1st. The Findlay Lab will work on unlocking the biosynthetic repertoire of bacteria, particularly on production of “cryptic” antibiotics, and on direct evolution of bacteria.

In the spirit of the “Get a Job, Ken!” series here’s an account of my job search. Hopefully it’ll be of some use to you.

Caveats

This write-up is a representation of my experience with the hiring process, and is not perfectly (or at all) transferable to your situation. Being a cis white male means living life on easy mode, and the effects are often subtle. There are also portions of the process I can’t address for confidentiality reasons; not least the exact details of my research proposals. 🙂

First, be lucky.

I really can’t stress enough how important luck is to this process. It’s ridiculous. For example:

Do you have a solid body of published work attached to your name? (Did things work more often than not? Where you in the right place at the right time? Were you the golden child?)

Was the bulk of your postdoc work published quickly? (Did great work, but it’ll be published next January? Too bad.)

Are there a lot of postings in your field this year? (Organic/Analytical/Biochem/etc.) Has a recent drought of postings caused a backlog of more experienced applicants to build up?

Are a lot of other people from your lab currently looking for work?

Is your subspecialty in demand? Does the department already have someone that does what you want to do?

Are your favoured universities even hiring this year?

Know Thyself. Then Pick the Research Field.

In the third year of my PhD I started wondering how professors decided the themes of their research. What is a good research project, and what separates successful researchers from those who struggle to get tenure? [1]

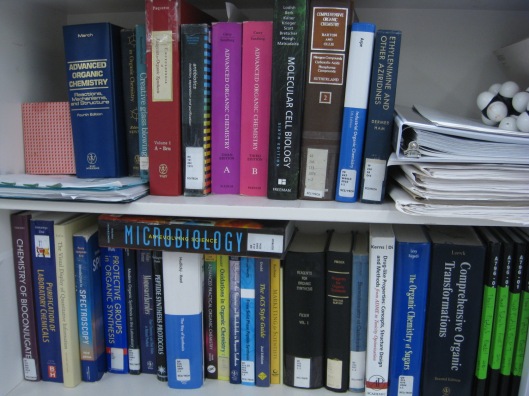

Part of this fascination made its way to the blog, and my review of “Marketing for Scientists” reflects my thoughts at the time. What didn’t appear on the blog was a series of informational interviews with associate professors. These culminated with an hour long conversation with a young “star” in Chemical Biology. I chose to speak with associate professors because they had just finished the early part of their independent career, and the trials and tribulations were likely still fresh.

One common theme that emerged from these interviews was to critically examine my own skills, and determine where my training and ideas differed most from other researchers. Work that stems from a rare mix of skills has a high barrier to entry, which encourages better funded labs to collaborate than compete [2]. My PhD work was entirely based around synthetic chemistry, but I had a BSc in molecular biology and biochemistry. There aren’t very many chemists that work at the interface of microbiology and organic chemistry, and I thought I could come up with some interesting insights.

But good ideas mean little if you don’t have the expertise to back them up, and I had no direct research experience with bacteria. Enter the postdoc.

I’m a committed Fox, more concerned with problems than the techniques needed to solve them. So I moved to a lab that used both synthetic chemistry and molecular biology/biochemistry to probe the production of bacterial and fungal natural products. This let me build expertise in “biology” [3], while still keeping my lab skills sharp.

When to Prepare? Early.

About five weeks into my postdoc I bought a notebook and started preparing for independent research. The goal at this point wasn’t to create fully formed research ideas, but to brainstorm up a few dozen major research projects that I might want to do.

As it turned out, the 2014-2015 hiring season started early, with the first major hiring spree (5 positions) closing on July 2nd. This was at least six weeks earlier than expected, and left me scrambling in mid-June to put together an application.

After that first posting, more jobs started to appear. Limiting my results to Canadian Universities, I found the majority of postings on either Indeed.com (search “Biology Professor”, “Chemistry Professor” or “Biochemistry Professor”) or NatureJobs. At the busiest time (August 1 – Oct 1) I also periodically scoured the websites of departments I was interested in. (Canadian) C&EN postings were limited, just a few ads appearing for only a short amount of time.

I made an excel file to track postings I was interested in, with columns representing each stage of the process. (Due dates, cover letters, proposals, and references). Each application also got its own folder on my hard drive, to cut down on the chance that the cover letter for school X would accidentally be sent to school Y.

Preparing The Application Package

The net is full of job application advice, most of which has even been collected in one convenient place by Dr. Becca of Fumbling Towards Tenure. This was an invaluable resource, every step of the way.

Beware the Triage

Every posting results in a hiring committee somewhere being buried under a small mountain of applications (200-300, on average). The result is a heavy triage that produces a workable shortlist of 20-30 candidates. You want to be in that shortlist.

While every committee member looks at different parts of the application, I spent significant time making the Cover Letter and Curriculum Vitae as clean and sharp as possible.

The CV is more than just a list of your publications stapled to your address. Don’t forget to highlight your awards, conference presentations, leadership roles, and the names and projects of any undergraduate/graduate students you may have mentored. Make the CV easy to read (large headings, numbered publication list, etc.), so that someone skimming hundreds of applications will stop and notice the details [4].

In the same vein, your cover letter is probably your first (and perhaps last) chance to stand out. It deserves the same care given to a research proposal, and should be personalized to each position.

Here is the basic layout I developed. This isn’t from the application that was ultimately successful, but is similar.

My address

The Date

Their Address

To Whom It May Concern,

I am writing in response to the department’s recent posting for a tenure-track assistant professor in [named field]. I have a strong background in [applied, specific topic], and have direct experience in [research fields 1, 2 and 3].

I am currently a postdoctoral fellow at the [Postdoc University], working with Dr. [Postdoc supervisor] under an [Independent fellowship]. My research here has focused on [Project that takes up half my time], as well as [Project that takes up the other half]. Prior to this position I completed a PhD at [PhD University] under the supervision of Dr. [PhD supervisor], working on [Topic of my thesis]. I began my career at [Undergrad University] melding a Molecular Biology and Biochemistry major with a Chemistry minor. There I completed an honour’s research project on [Undergraduate research project] under Dr. [Honour’s supervisor], as well as performing research under a [Undergraduate grant] in the lab of Dr. [Grant supervisor], working on [Other undergraduate research project].

As a professor at [This University] I will focus on understanding [Topic of proposed research project 1], as well as [Topic of proposed research project 2]. [Research project 1] may be used to improve our understanding of the [Faculty research theme] studied by Dr. [Member of the department], while also potentially uncovering [Faculty research theme 2] of use to Dr. [Other member of the department].

Attached to this application please find a curriculum vitae and description of my teaching philosophy. Drs. [A, B, and C]l have agreed to support my application, and their contact information is also enclosed.

Please don’t hesitate to contact me if you require any further information.

I look forward to meeting all of you.

Sincerely,

Brandon Findlay

Hard copy applications were signed, but I didn’t worry about sending in an unsigned pdf. What was important was the paragraph highlighting the work of faculty in the department, and the few words detailing how your research could help theirs. Not only could this spark their interest (no telling who’s on the committee), it also shows that you’ve done a bit of homework, and could be a good fit for department you’re applying to join.

The Teaching Statement

Teaching is a huge part of any university. In my teaching statements I detailed my teaching background, leaving the overall message (I love to teach and am good at it) as subtext. Specifically, I outlined my undergraduate tutoring experiences, my successes as a TA, and the 1 on 1 mentoring I’ve done as a graduate student and postdoc (as well as this blog, obviously). I closed by explicitly stating what courses I would be happy to teach (with course codes), and mentioned a potential 4th year/graduate course I could create.

In early applications this section ran on for far too long. Limit yourself to one page.

The Research Plan

I liked preparing the research plans, and may have spent too much time researching and refining the ideas. Aesthetically, include as many images as possible (I aimed for 3-4 per proposal) and don’t be afraid to use white space. Putting empty lines around your specific aims is costly, but can also draw attention to the impact of your work.

I shamelessly copied the research summary layout put forward by Kenneth Hanson. The full proposals were subdivided into sections titled Introduction, Current Solutions, Headings 1-3 (subject specific), Challenges, Aims (bullet point) and Significance.

In other words, my standard layout, slightly tweaked.

Post Application

I aimed to complete and send in each application about 7-14 days before the deadline. This was somewhat arbitrary, but fit well with the timeline for reference letters (past the first application each letter was requested at least two weeks in advance).

Once the application was submitted and acknowledged by the university there was a long quiet period. About two thirds of the applications ended with someone from the department contacting me about 4-6 months after the deadline, to say that either I didn’t make the shortlist or they were going with another applicant. Most of the rest gave no further response.

One department asked for a phone interview.

The Phone Interview

Based on structure and common questions of the phone/skype interview, most hiring committees don’t triage their shortlist like they do the initial mound of applications. Rather, during the phone interview candidates will actively remove themselves from consideration, generally by demonstrating either a lack of preparation or a lack of interest in that specific department/university. Those that remain can then be further debated and/or offered an in-person interview.

Phone interviews are short (~20 minutes), heavily scripted, and largely standardized. As a result they’re relatively easy to prepare for. The tenure track megalist contains a number of good posts on potential interview questions (here’s the link again), and there’s plenty of other sources around the net (pdf). In my case I was asked all but one of the questions during practice interviews.

There is one question that you have to answer well, or the committee will likely not invite you for an interview. It is in every list of potential questions, and was in fact the first question I was asked.

Why here?

“Why university X?” “Why this department?” “What attracted you to this position?” How you respond says a lot about whether or not you’re a good candidate for this department.

The 1st In-Person Interview

Congratulations on your interview! Now there are only three things you need to demonstrate to seal the deal.

1. Can You Teach?

You must be able to deliver a competent undergraduate lecture, and to articulate the key points of your research to a broad audience. The primary evaluation metric for this is the public lecture, a 45-60 minute talk about your prior research activities.

Public speaking skills aside, this talk is really a demonstration of your ability to synthesize a large body of work into a coherent story. Both my PhD and postdoc work have involved antibiotic research in some form or another, so I was able to show an evolution of my interests from making antibiotics to understanding how they worked (this was a biochemistry posting, mind).

2. Can You Perform Independent Research?

From the public lecture I moved immediately to the private chalk talk, outlining what I planned to research as a new faculty member. Some have had rough experiences here.

In general I subdivided my main research themes into modules or projects, so that once through the introduction(s) I could detail the first 2/5/10 years of the lab’s research, or in the interest of time stop at an earlier stage.

For each research theme I introduced a relatively broad research problem and the current ways it was being addressed. I then introduced my idea, couching it as an elaboration on already published material. It took a fair bit of time to explain the theoretical underpinnings with previously published material, but 1) committee members may have diverse backgrounds and know this research problem well, and 2) one of my ideas has a lot of unknown unknowns, and I wanted to demonstrate that the idea was well grounded and that I had foreseen several stumbling blocks. Come what may, I can make things work [5].

As with the written research proposals, it’s important to show that you’ve given just as much thought to the details as the big picture. I included potential funding sources for each project (down to the NSERC evaluation groups), and found a local biotech company I could potentially collaborate with [6].

3. Will You Make A Good Colleague?

Barring the odd high-profile move faculty that receive tenure are appointed for life. That means that everyone from the Dean to the academic staff will have to work with the new hire for a long time. Ensuring you will be a good colleague and fit in well with the department’s culture is a crucial part of the interview, and what consumes the bulk of the visit.

I found Hope Jahren’s take on this process to be quite helpful. Her focus is really on the entire interview, but there’s a common thread.

Be nice. Be happy. Demonstrate that you’re the sort of person that (metaphorically) always puts on a fresh pot of coffee if they drain the pot, and won’t complain bitterly if someone else left the pot empty.

My experience with the 1 on 1 faculty meetings varied wildly, from having my work challenged to faculty excitedly presenting the details of their own research. The best professor took me throughout the campus, introducing me to support staff and key contacts.

The Post-Interview Phase

It took me weeks after the interview to regain my centre.

Once a few weeks had gone by though I was well rested, but constantly checking my email. Most schools interview three candidates, but few will contact choices 2 and 3 until someone has officially accepted the, which can be months. The longer I went without news (on a day to day basis) the worse it felt.

Eventually though, the feeling faded. And when the call did come it was a very pleasant surprise.

Negotiating and Postscript

I’ve already covered what to look out for when negotiating the startup package, so won’t address that further. One thing I will add, if you have a spouse involve them in every part of this process [7]. They may not have a scientific background, but can still serve as a sounding board for ideas, a partner in mock interviews, and a source of advice. This goes double for the negotiating process, as deciding to accept an offer means relocating to a new city/area/country for the next thirty plus years.

If you have any questions about any part of this process I’d love to hear them in the comments, and will do my best to provide answers. If you’d prefer to contact me directly I can be reached at Brandon.Findlay@zoho.com

Good luck.

[1] Spoiler alert: Money goes a long way.

[2] Some examples of rare skills/focuses: high nitrogen compounds, high speed photography, metal-organic frameworks and crystallography, and (my focus) whole-cell biochemistry. In some fields the barrier to entry is technical. If your work requires a really expensive piece of equipment, only a few labs can do the work you do (that goes double if you have to build the equipment yourself).

[3] My work tends to draw from a lot of related fields. Some of it (cloning, recombineering, protein expression) is classical molecular biology, while other parts are definitely either biochemistry (antibiotic characterization, model membrane studies), natural product chemistry (preparative metabolite isolation and ex vivo biosynthesis) or microbiology (growth inhibition). To save time I’ll simply refer to the lot as “biology”.

[4] Here’s a slightly redacted version of the CV I sent out, on the off chance you may find it helpful.

[5] Of course, research success also comes from recognizing opportunity when it knocks. A number of profs I’ve talked to have been almost perversely proud that they never did anything outlined in their initial research plans, or only found success after none of their original ideas worked.

[6] Company XXX is based two kilometres away, works with these types of therapeutics, and might be interested in licensing our work or providing funding sounds a LOT more impressive than “I will collaborate with pharma companies”.

[7] Thanks, Lisa! You’re awesome.

I was recently gifted with a copy of “

I was recently gifted with a copy of “